Add to Cart

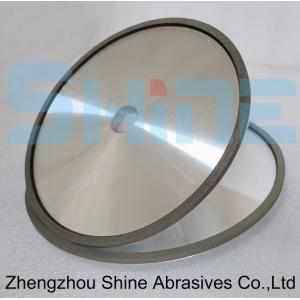

Resin bond diamond grinding wheel suits to grind carbide, hard steel, hard alloy, all kinds of serrated teeth, sharpen edges, milling cutter, Suitable for the surface grinding and outer circular grinding of cemented carbide measuring tools, tungsten steel, alloy steel.Also suit for grinding high-alumina porcelain, optical glass, agate gem, semiconductor material, stone, etc. We will provide a complete solution for tools manufacturing process, including fluting, gashing and clear edge, relief angle grinding .

| Diamond Grinding Wheels |

| Diamond + Aluminum Base |

| 100mm/Customized |

| 40#-600#,Customized |

| Longer Working Life,High Grinding Efficiency,High |

| OEM ODM |

| 1A1, 1V1, 6A2, 11V9, 12A2,Customized |

| 1 Piece |

| Resin Bonding |

| Cartons |

| 100000 PCS a Year |

| Diameter: 50mm-200mm |

We can customize different shapes of grinding wheels based on your grinding wheel drawings, grinding wheel models, and other information; Meet the grinding needs of tools in different situations.

According to the diamond surface metallization model, there are three layers of coating on the diamond surface, namely carbide layer, alloy layer and plated metal layer. The metals and alloys used for plating mainly include W, Cr, Nb-Ti, Mo, TiN, NiWB, etc. There are many methods for diamond surface metallization, such as electroless plating and electroplating, vacuum physical vapor deposition (PVD) and vacuum chemical vapor deposition (CVD), powder covering sintering, etc. Currently, the more commonly used plating methods are vacuum physical vapor deposition (PVD), vacuum chemical vapor sintering (CVD), and vacuum micro-evaporation plating technology.