Add to Cart

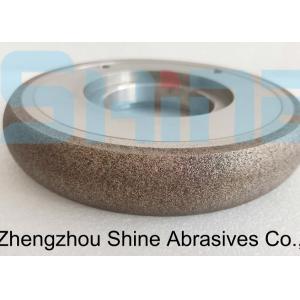

8 Inch Metal Bond Diamond Grinding Wheel For Tungsten Carbide Roll

Shine Abrasives Metal Bond Diamond Wheels For Tungsten Carbide Roll

grinding and specific shape forming.

Metal bond diamond grinding wheel has good mechanical properties and self-sharpening, high grinding efficiency,

large machining allowance, high diamond holding force, good formability, good shape retention and long service life.

It can be used for the processing of quartz crystal, cemented carbide, glass, composite sheet, ferrite, engineering ceramics,

architectural ceramics, ceramics (thermal elements, etc.) for the electronic industry and refractory materials;

cemented carbide roller ring is also called tungsten carbide Alloy roll ring is an important component with

relatively large consumption in the rolling of steel bars and wires, and is closely related to the apparent quality,

dimensional accuracy and cost of the rolled steel.

The drawing of Shine Abrasives Metal Bond Diamond Wheels For Tungsten Carbide Roll Shape Grinding

Main sizes form of Shine Abrasives Metal Bond Diamond Wheels For Tungsten Carbide Roll Shape Grinding

| Abrasive Material:Diamond | Bond Type:Metal |

| CBN Grit:D126 | Wheel Diameter: 8inch 200mm |

| Wheel Bore:76mm | Wheel Weight:6.0kgs/PC |

| Wheel Thickness:35mm | Concentrate: 125% |

Other standard sizes also are available as requested.

Features of Shine Abrasives Metal Bond Diamond Wheels For Tungsten Carbide Roll Shape Grinding

Highest wear resistance and profile retention

Thermally resistant

Many sizes and Diamond grits are available.

Long time wheel working life

Question.

What's metal bond diamond grinding wheel?

Metal bond diamond grinding wheel mostly uses bronze and other metals as the bond,

and is manufactured by high temperature sintering method.

metal bond diamond wheels have features:high bonding strength, good form-ability, high temperature resistance,

good thermal conductivity and wear resistance, long service life, and can withstand large loads.

Application pictures for reference.