Add to Cart

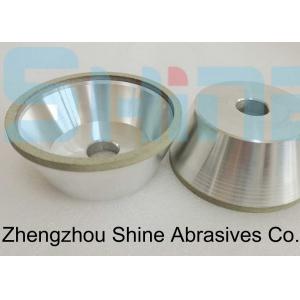

Vitrified Bond Wheels 11A2 Bowl Diamond Wheel For Tungsten Carbide

Shine Abrasives vitrified diamond wheels main are used for Cylindrical grinding, surface grinding for Tungsten Carbide tools.

Also are used for regrinding PCD cutting tools, PCBN cutting tools, CVD tools, MCD tools,

The vitrified bond diamond grinding wheel has high strength, good heat resistance, sharp cutting,

high grinding efficiency, not easy to heat and block during grinding, and small thermal expansion to control machining accuracy.

Widely used in wafers (semiconductor silicon wafers and solar silicon wafers), diamond composites,

diamond polycrystalline, diamond tools, cubic boron nitride, tungsten steel (tungsten carbide),

new engineering structural ceramics, gemstones, crystals, rare earth materials (magnetic material)

and other highly hard and brittle materials in machining.

The drawing of Shine Abrasives Vitrified Bond Wheels 11A2 Bowl Diamond Wheel For Tungsten Carbide

The main sizes form of Shine Abrasives Vitrified Bond Wheels 11A2 Bowl Diamond Wheel For Tungsten Carbide

| Abrasive Material:Diamond | Bond Type:Vitrified |

| CBN Grit:Diamond 120# | Wheel Diameter: 100mm |

| Wheel Bore:20mm | Wheel Weight:1.0kgs/PC |

| Wheel Thickness:40mm | Diamond rim size:5x4mm |

Features of Shine Abrasives Vitrified Bond Wheels 11A2 Bowl Diamond Wheel For Tungsten Carbide

High strength wheels

Good heat resistance wheels

Sharp cutting

Good shape forming and good self-sharpening

Low grinding temperature when working

Many different diamond grits are available.

Application picture for reference.

Attention:Workers should ensure that you are fully informed on the safe operation of abrasive cutting and grinding wheels